Fixing the rust hole behind the drive side tire. Wish I could find the pics from when I tore the carpet out 8-9 years ago and found the galvanized sheet that was covering it and siliconed in place. I cut out most the rust in that area then so it hasn’t spread. I’ve been internally debating on pulling the tank one of these days and cutting the bed floor to sink it down in from the top. I’ve got some rear bed floor panels I need to pick up from a friend. And I’ll likely build up the floor so it covers the tank yet again. It’s gonna be a rock magnet hanging under there. We shall see though. I’ll probably never finish this damn thing.

But after this is done I’ll move on to making clearance the floor for the tcase shifter. I’ve gotta get the slip spline turned down so I can stuff it in the DOM for my front driveshaft. 1350CV at the tcase end and 1410 yoke on the axle end. Hopefully Monday I can get it done local. I’ve realized you can’t really tell people but the bare minimum of what you’re doing because they get spooked pretty easily. 2 shops that answered the phone today said no 3 didn’t answer because it’s Friday, I understand that.

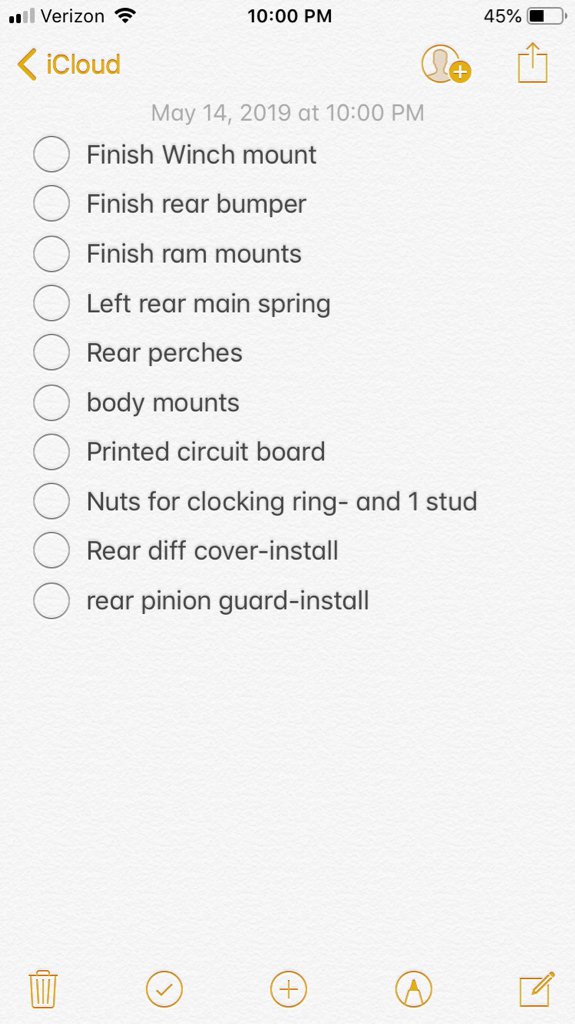

Tomorrow I’ll be pulling the driver side spring pack to get that cracked main leaf swapped out. Then I’ll weld on the new spring perches to get a tiny bit better pinion angle. I’ve still got to get a 1410 slip yoke for the rear shaft so can use my U bolt style yoke on the 14 bolt out back. I’ve got a Barnes4wd 13 bolt cover on the way and I’ve already got the pinion guard here at the house.

If I can have it 4wd before Wednesday next week I’m planning on driving it to uwharrie and screwing around up there for the weekend. Telling people this in person has been rather comical, the puzzled look on their face when I say it, is great. I mean worse care scenario it comes back on a trailer or tow truck. I don’t follow that whole build a drivetrain fuse bullshit because screwing a yoke all to shit really can make a bad day. So throw the beef at it and build it so it’s reliable.

I added a Dakota digital Speed sensor signal generator to the tcase last week. It’s really cleared up the drivability, but need to dial in the pulses via the ECM. I’m sure that will wake it up a little more, but it’s been fun to drive. Having the ram assist makes it very easy to drive at highway speeds and it seems to motivate those 38s to maneuver in parking lots easily. It will also take the stress of the frame where these older GM platforms are prone to cracking. I do have a ORD steering box brace and frame reinforcement pieces to install as well.

I’ve got some 1.5 x.120 wall DOM I was going to use for the shock hoops. But I think I’ll just try and pick up some 1.75x.120 wall to do them. I plan on doing the cage out of the same tubing and I want it to flow into each other pretty well. These chassis are like pool noodles and flex like crazy. So I want to tie it together from the core support to the rear bumper. I’m sure the body panels will appreciate it.

Which brings me to I need to also change out all my body mounts with the energy suspension ones I picked up a few years ago. It’s almost like if I used all the parts stuffed inside my nasty ass garage it would clear out so much space.

I still need to pick up some inner chromoly shafts for the 60 up front. I’ve got 2 extra GM 60 housings. Pretty much all the stock parts coming out of the 60 in the front of the k5 will be used to build another one to either sell or I’m sure I’ll find something to put it in.