ghost

Well-Known Member

- Joined

- May 25, 2006

- Location

- Hartsville/Camden,SC

Nov 9th for Gulches?

Possibly the following weekend. I may be riding on some 29" Maxxis tires with some buddies from ECGS and Oliver's on the 9thNov 9th for Gulches?

Hmm well let me know. I'm going to the Veteran's ride on the 9th. I'd love to see you on 3d with the Ford.........Possibly the following weekend. I may be riding on some 29" Maxxis tires with some buddies from ECGS and Oliver's on the 9th

Possibly the following weekend. I may be riding on some 29" Maxxis tires with some buddies from ECGS and Oliver's on the 9th

I am free also

Yeah, but they're invited

Didn't know you were a biker. Obviously you're welcome to join if you'd like. You do like elevation gains, don't you?

hell probably not on 4 wheels either..

hell probably not on 4 wheels either..The ol' girl continues to follow buggy lines and the sheetmetal proves that fact. Me and my crew recently had a killer weekend at Choccoloco in Alabama. The blue beeyotch performed great and aside from some pass door carnage, no problems

But an annoying thing keeps happening. The transfer case studs and nuts back out after a ride or two. I keep an eye on them, but they'll do so quickly. You can tell by watching the transfer case shifters start moving all over the place inside the cab.

So today I fabbed a DIY Atlas support ring and crossmember. I got the kit from eBay for line $60 and trimmed to fit. The crossmember is 1" x 3/16" square tubing. I welded a nut in the end of each end so it can be through bolted with 7/16" bolts. It rests in a pocket in the frame to help locate it.

All in all, a success. Now I'll pull the Atlas to access the studs and replace them with better hardware.

I hope @mcutler can sleep at night knowing such a high level of fab skills exist on my side of I40.

View attachment 309179 View attachment 309180 View attachment 309181

Funny, I recently got a lesson from Matt on the 3 legged table theory (motor mounts and trans mount). That 4th leg you just added can stiffen any torque the driveline produces. Might cost you a bell housing.

Everyone has different experiences.@BigSouth that is a valid point. I've ran similar support rings on 2 prior rigs that had doublers

However...

In my case, all 4 mounts are the same, sleeve and bushing. Engine mounts are oriented parallel to each other as are the trans and Atlas support, albeit they are perpendicular to the engine mounts.

The Atlas ring isn't so much a mount as it is there to keep it from pulling off the back of the transmission. It will still torque side to side as the clamping rig will still allow the output housing to rotate a minor amount. If it were more rigid, yes there would be a potential for BH damage

Also on my side is the fact a C6 housing is cast iron and very resilient.

Good point and I'm open to discussion on this topic.

Everyone has different experiences.

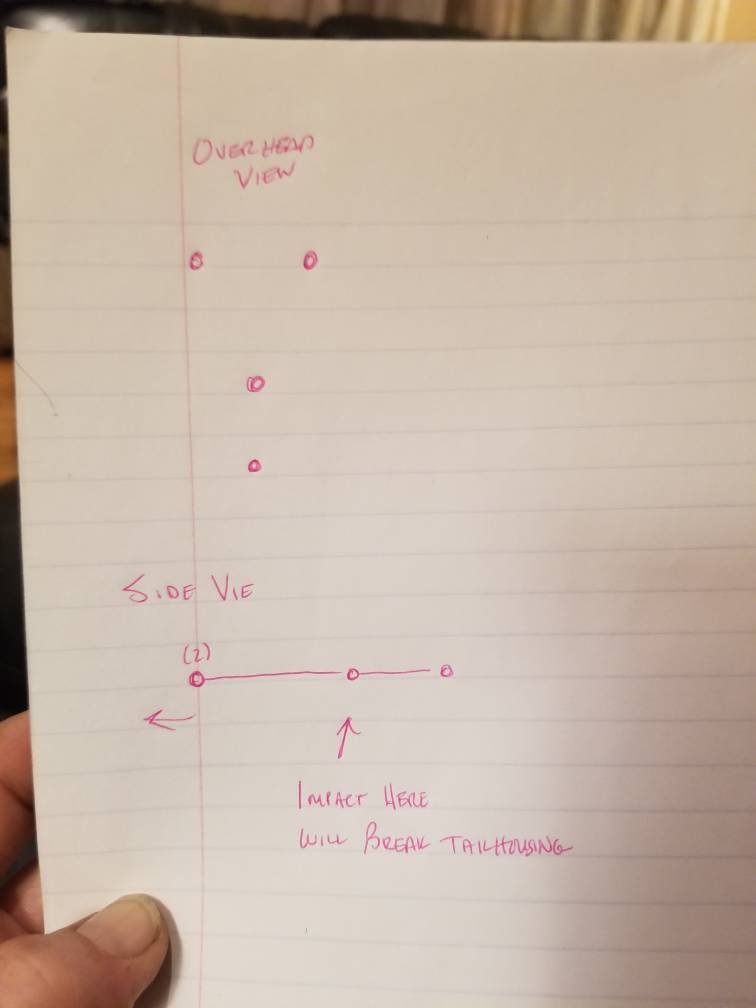

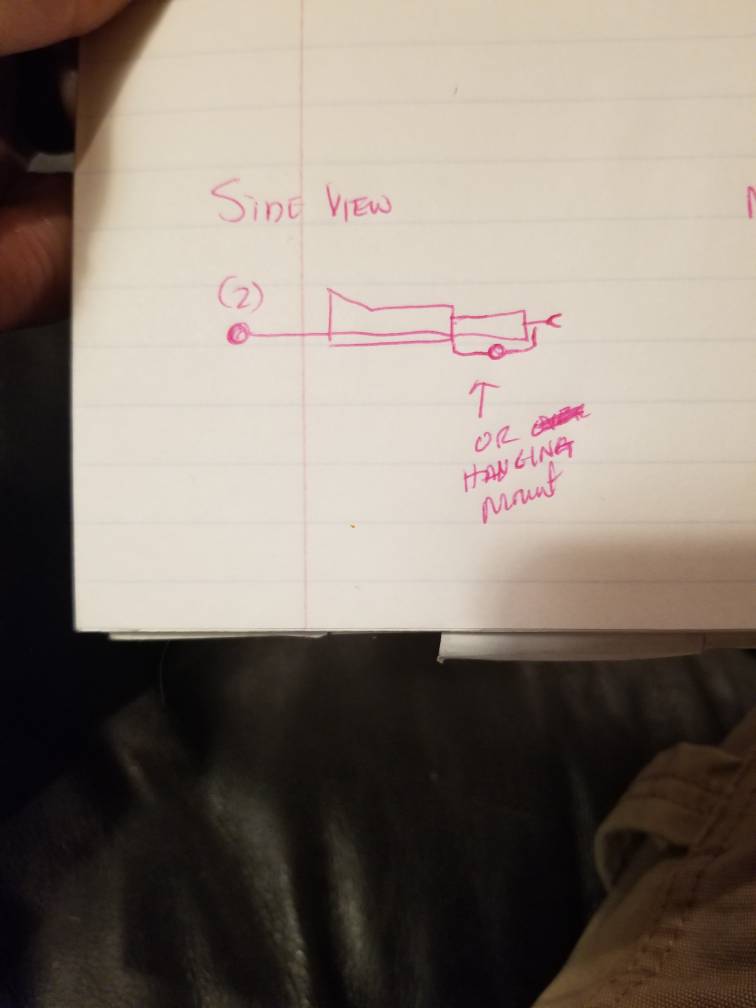

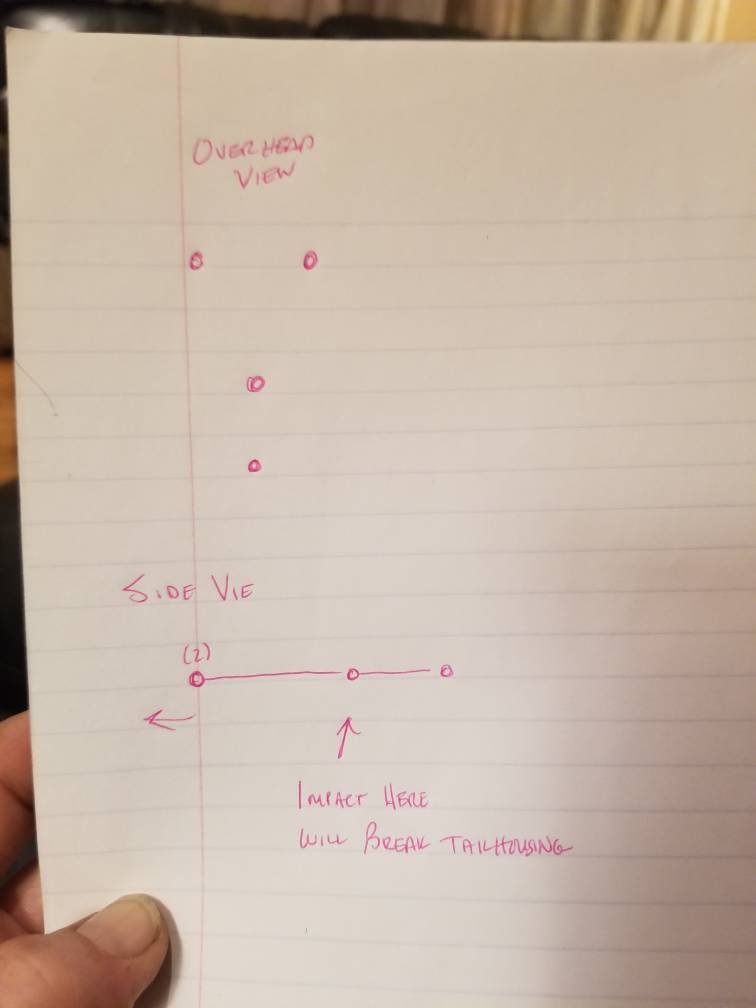

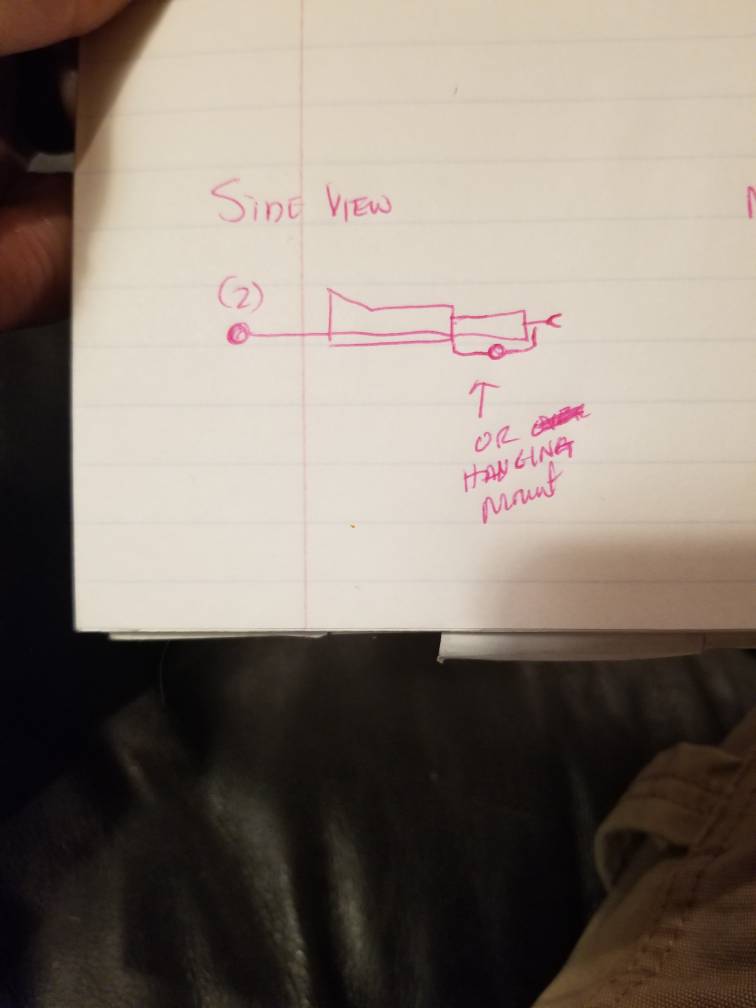

I'm a firm believer in the 3 leg table design. Adding a fourth leg is not an issue of engine torque, it will do its job in the respect. It's the chance of an impact anywhere between the engine mounts and last mounting point, in your case, the atlas ring. I've lost 3 tail housings when having a ring, due to belly impact; the drivetrain is over-constrained with 4 point design. Bell housing is not the issue, tail housing of the transmission is the week point.

Crude drawings included

Sent from my SM-G892A using Tapatalk

Thanks @mcutler, feedback always appreciated. I totally see your point, that any impact between front and back mounts would/will look for a weak point in between.

In my case, would you support (see what I did there?) my thoughts as long as my skid plate is rigid enough so the crossmember/support mount wont see impact, it shouldn't be an issue?

My skid is quite massive, braced to Hellanbach, and perhaps most important in this case, independent and away from the new crossmember.

Indeed. As long as the neither mounting tube is in contact with a rigid skid, should serve fine. You can see this being formatted in many buggy designs with a separate tube an inch or so above the belly skid, or with a hanging mount. I fully agree that supporting an atlas isn't a bad idea, so long as your mounts allow twist of the chassis (especially in a stock C channel frame and transmissions prone to tail housing stress failures) and stay out of the way of impacts.But it’s inline with the trans mount. Probably only 18-20 inches aft of the trans mount. The added stiffness should be marginal compared to what the motor mounts are handling, no?

Sent from my iPhone using Tapatalk

I stumbled back on this thread looking for a pic of my dovetail for another forum.

Truck is still ready to do it's thing. No real upgrades on the horizon as I really just want a buggy. No immediate plans or anything, but hopefully within a year or two I'll have a Bent Fab chassis with all my powertrain and drivetrain in it. EB grille, retro paint and a #BTL decal.

EVOYou are basically describing the buggy i want, as well. Which chassis are you looking at? Guessing CK1/EVO if you are skinning. I prefer the front of the Cliffhanger/Grunt/CH2

Just do it already and get the chassis on the way.

Just do it already and get the chassis on the way.

...hmmm, I could just get two coming[emoji6]All kidding aside.

If that chassis ends up in my workshop, it takes up money making space and time. If it ends up at my soon to be home shop, I tinker on it in my free time.

That's the difference in my head.

EVO

I spoke with Tim at length last year and actually drew out my plans based off his spreadsheet. Money-wise, it is completely doable. I would rather get my shop built first so I'm not 45 minutes away from working on it in my spare time.