You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

D-6

- Thread starter MetalCraftSolved

- Start date

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

I would plan for at least .003-.005 which is only on the radius. If you have that piece hard coat anodized like you should thats another .003. Hopefully you not drawing any of this chassis that tight.

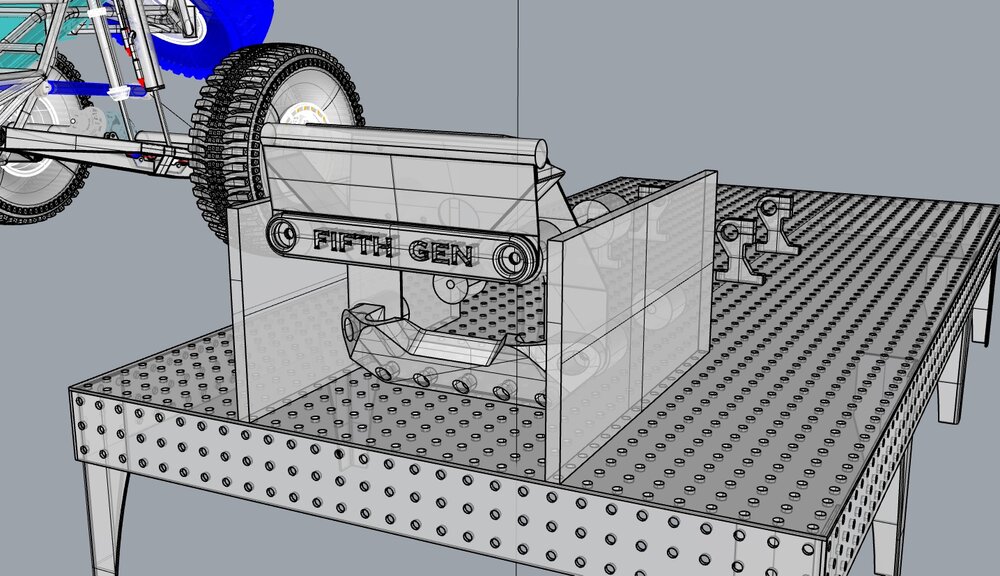

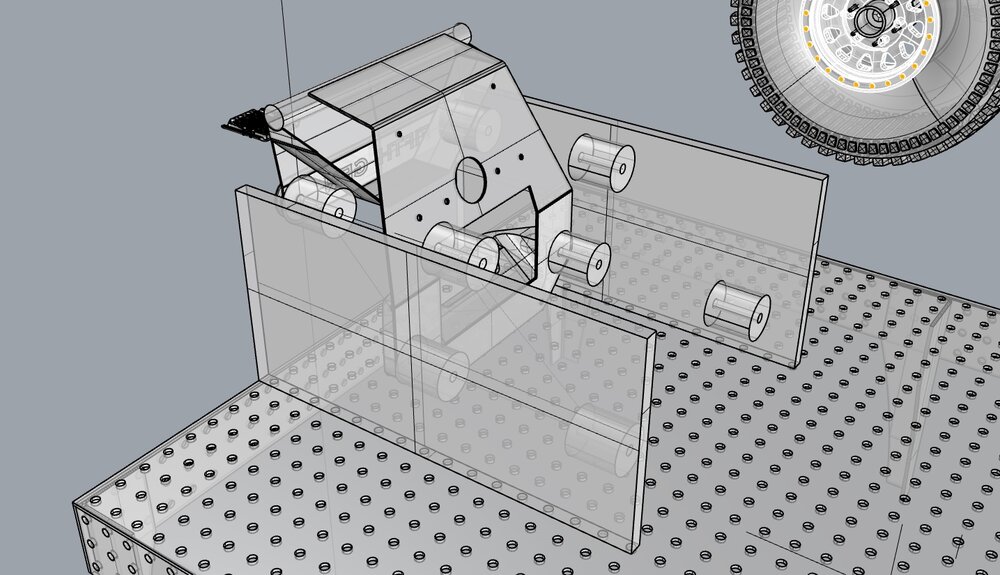

It's drawn tight. It's pretty tight on the tubing right now like Rob was saying. There is a 0.035 gap between the tube, and the armor. I'm actually looking into it being a jig fixture at the moment. I'm thinking draw it to bolt on the chassis table, or draw the chassis table to bolt to it. Vice, Versa. I think I can just bolt it to the fixture table and use it as mock up when I bend the center belly rails.

Last edited:

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

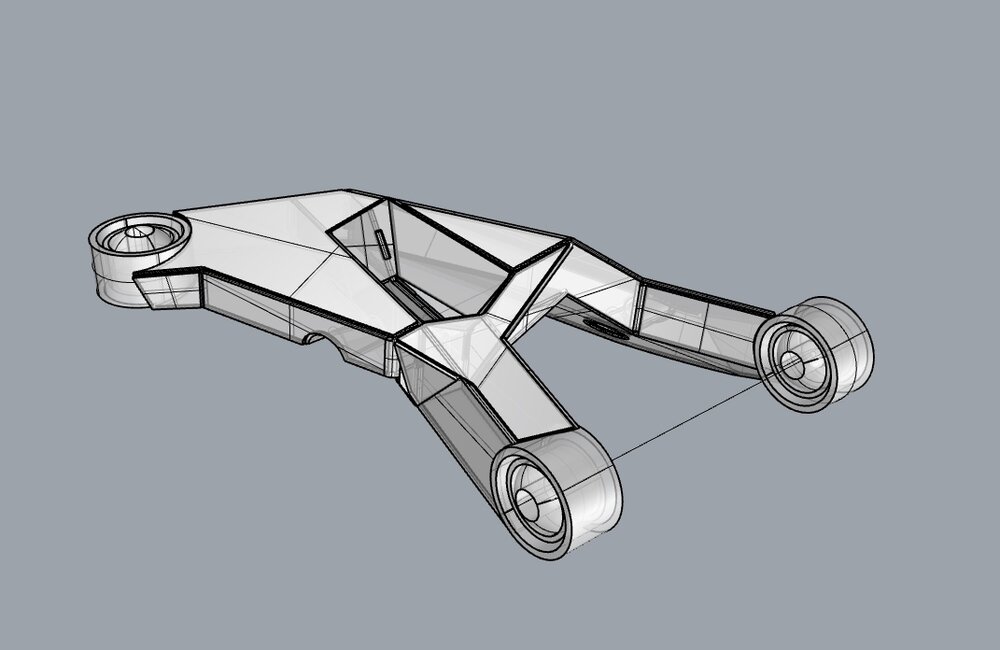

Oh, we did a test run on some metal with the lower control arm a while back. Everything checked out. The digital model is good.I still want to see real metal. When will that happen?

So are you planning to build this on your own dime. Or try to find someone to front the cost?Oh, we did a test run on some metal with the lower control arm a while back. Everything checked out. The digital model is good.

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

So are you planning to build this on your own dime. Or try to find someone to front the cost?

I'll probably pen this drawing as far as I can push it, and then group up with some people that can finish theorizing everything I can't figure out.

bigassedredjeep

Well-Known Member

- Joined

- Mar 23, 2005

- Location

- Middlesex, NC

This thread is so entertaining!

This thread is so entertaining!  Can't wait to see who all is in this "theorizing group"

Can't wait to see who all is in this "theorizing group"Hopefully they're theorizing where they can each get 100k to pitch in, otherwise its just a digital art project.I'll probably pen this drawing as far as I can push it, and then group up with some people that can finish theorizing everything I can't figure out.

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

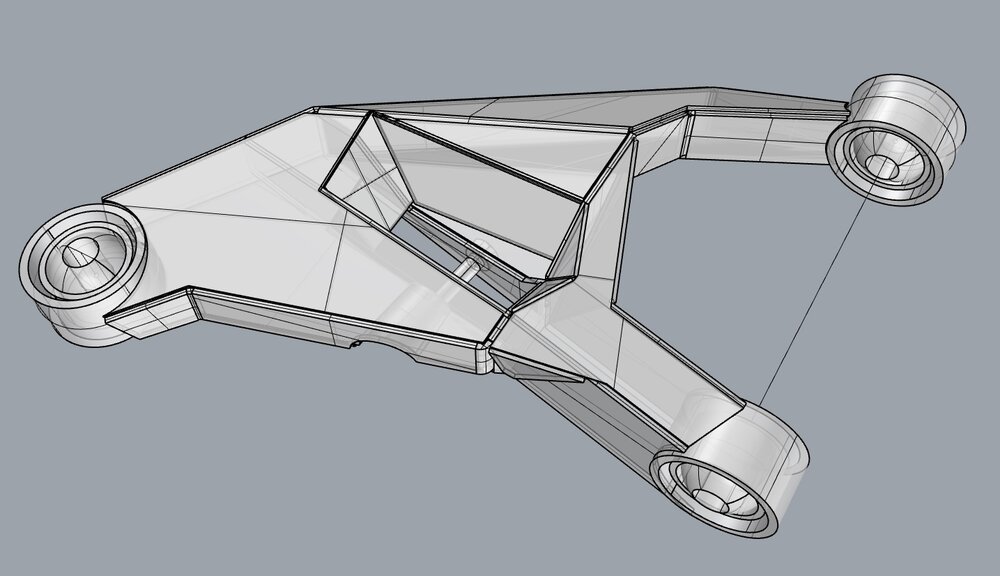

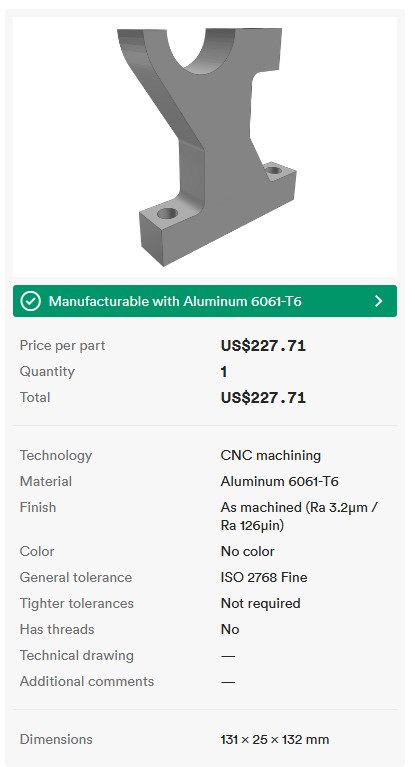

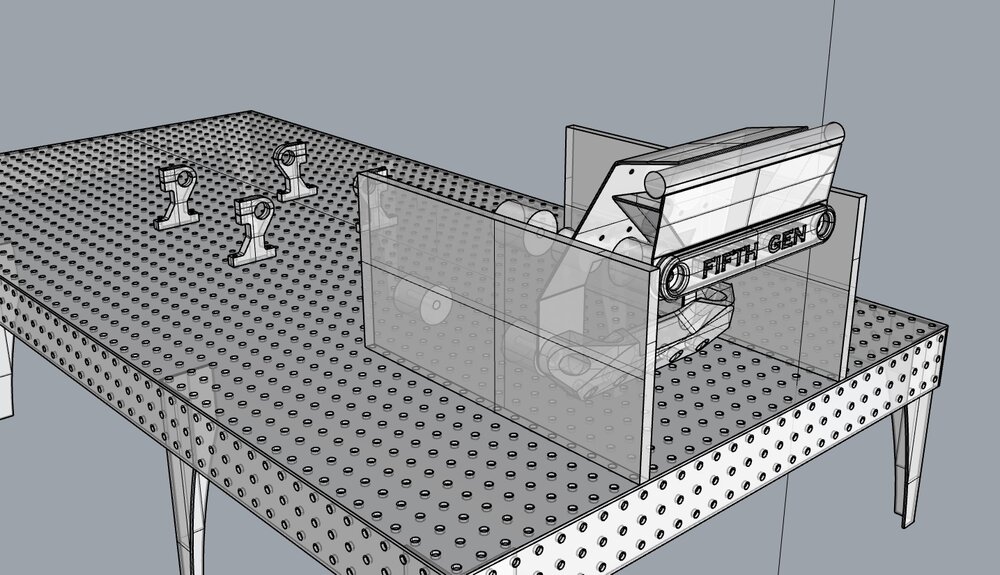

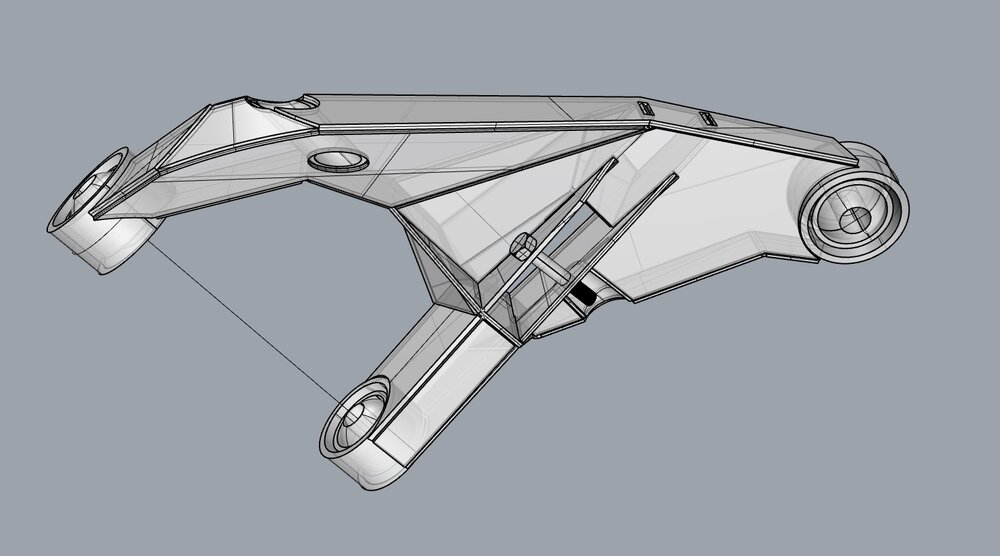

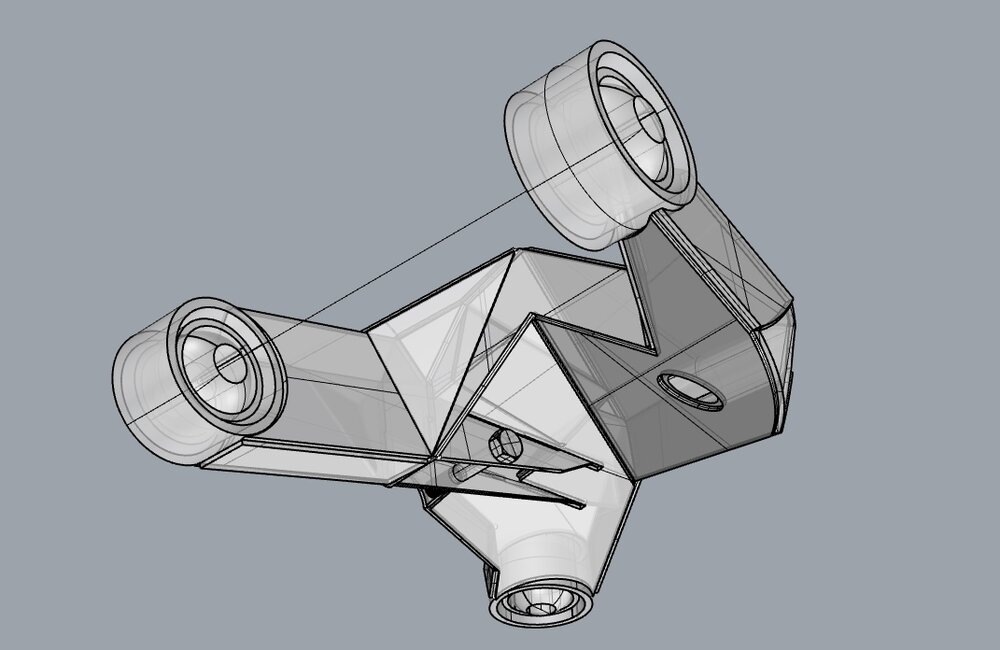

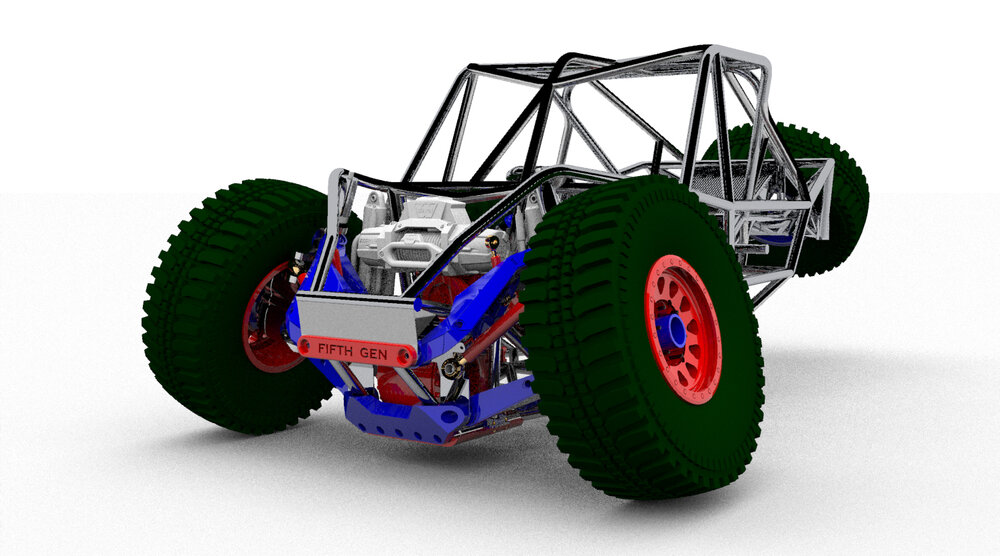

Upper control arm. There's a lot of people's work I've been around influenced into it. I might would call it "what I've learned" few more details, and it's there.

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

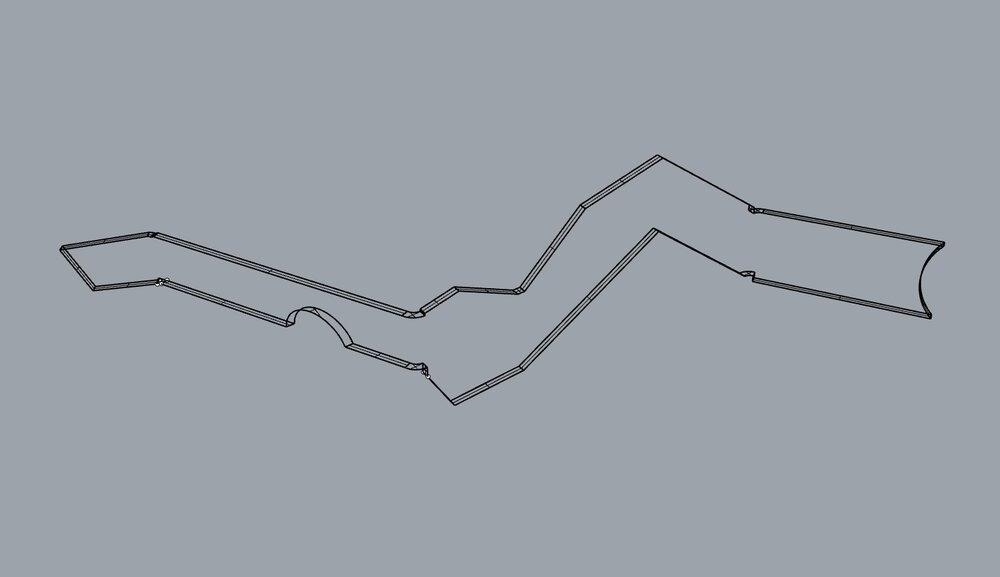

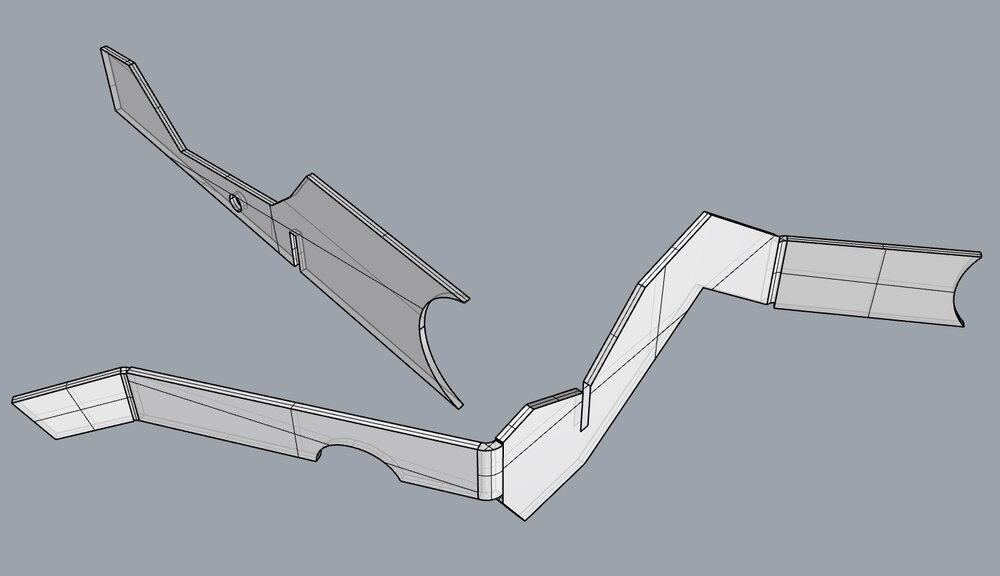

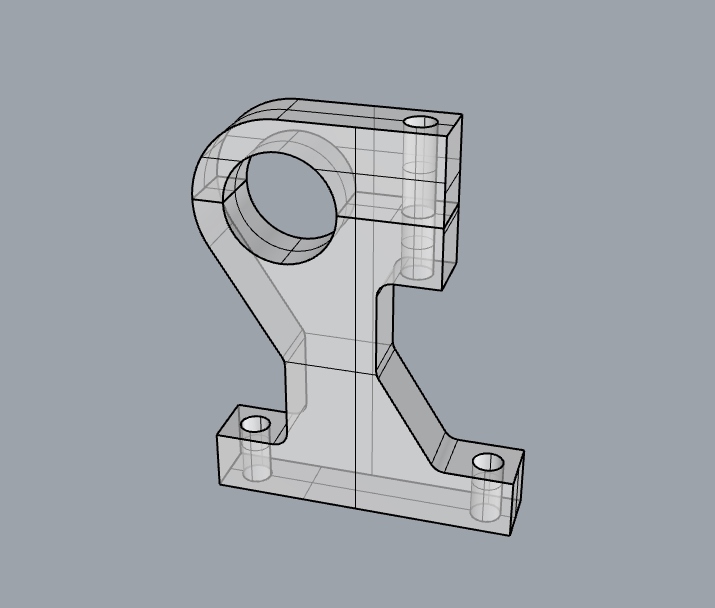

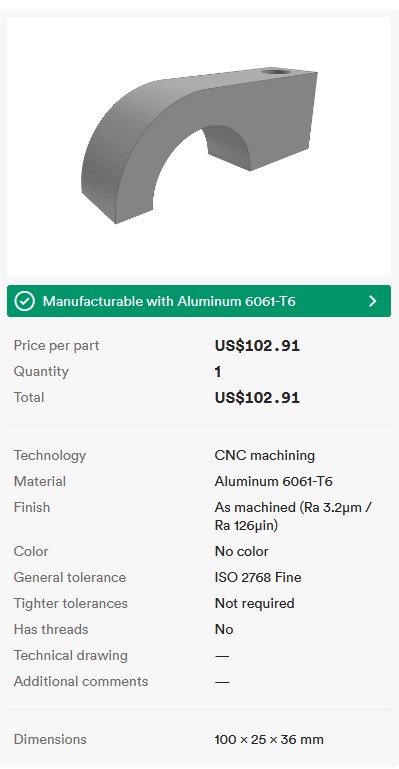

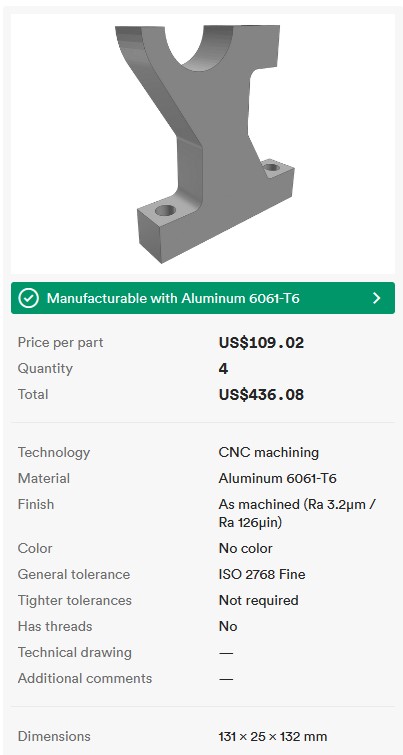

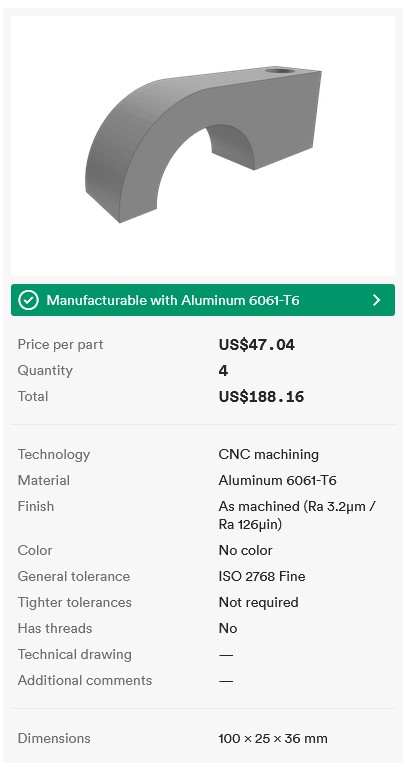

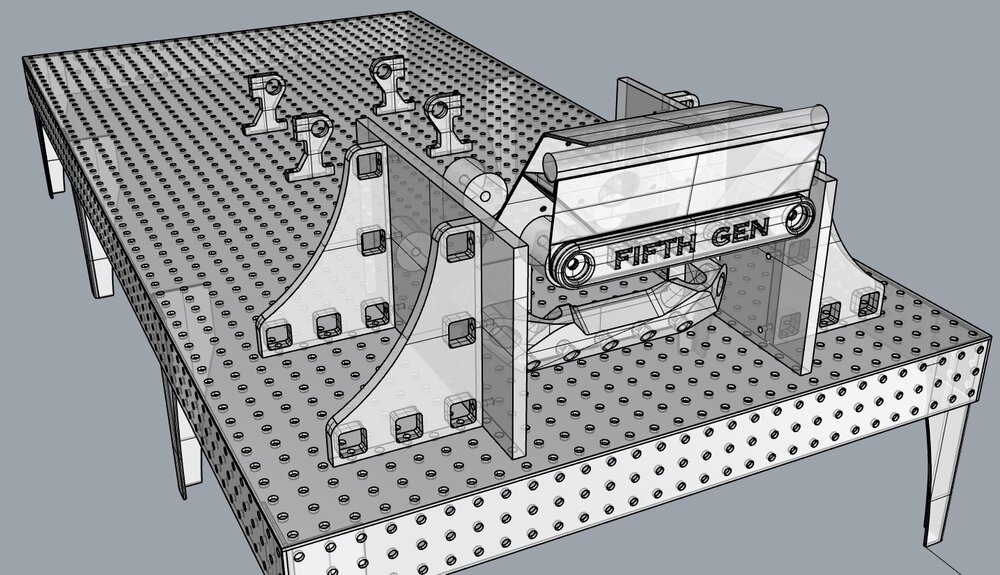

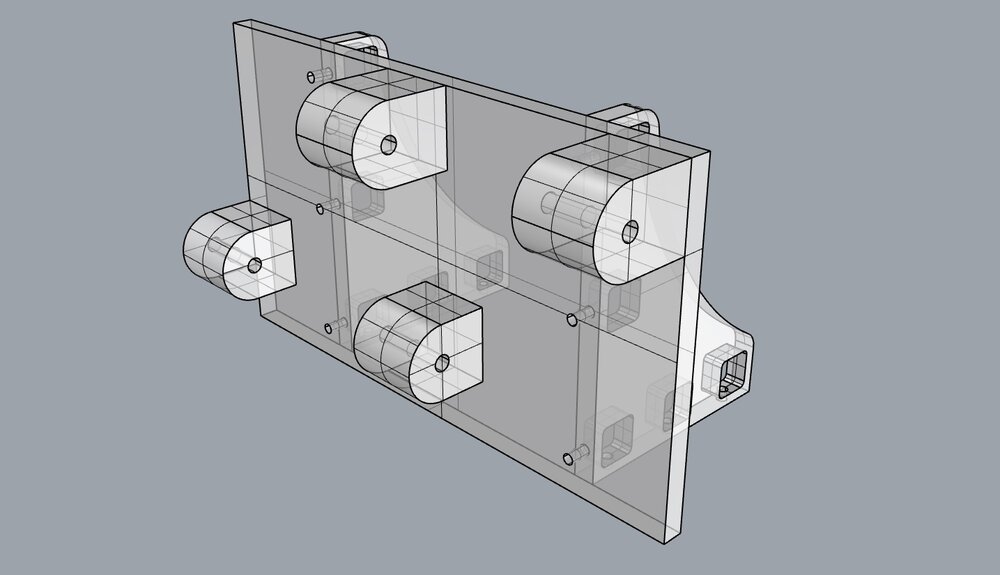

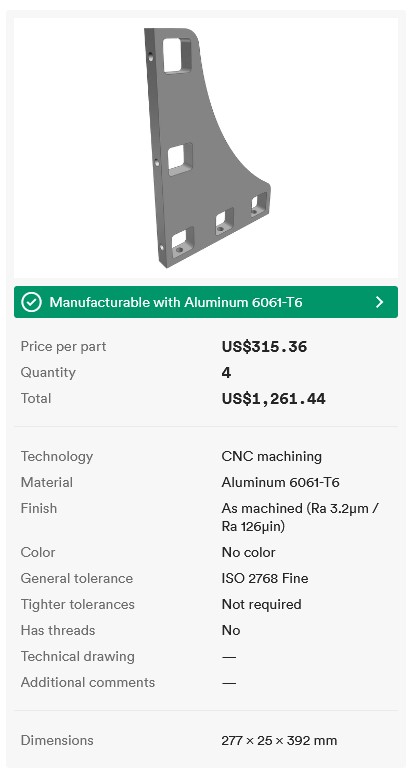

Billet belly rail clamps. Ordering 4 sets cuts the price in half. First time I've noticed those tubes aren't flat with the earth.

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

We'll still be using these billet fixtures 30 years from now. It's detail deep diving, so into the abyss.

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

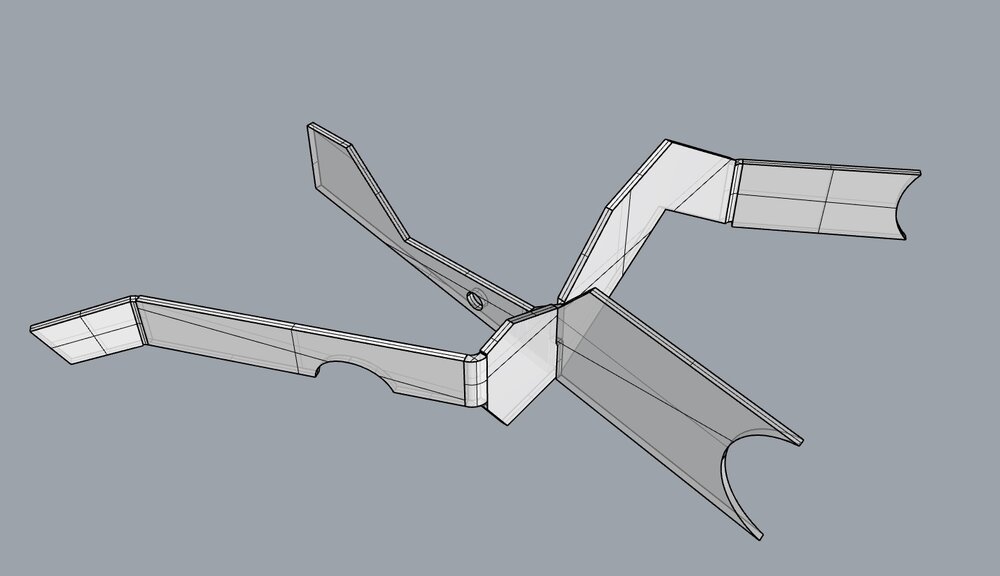

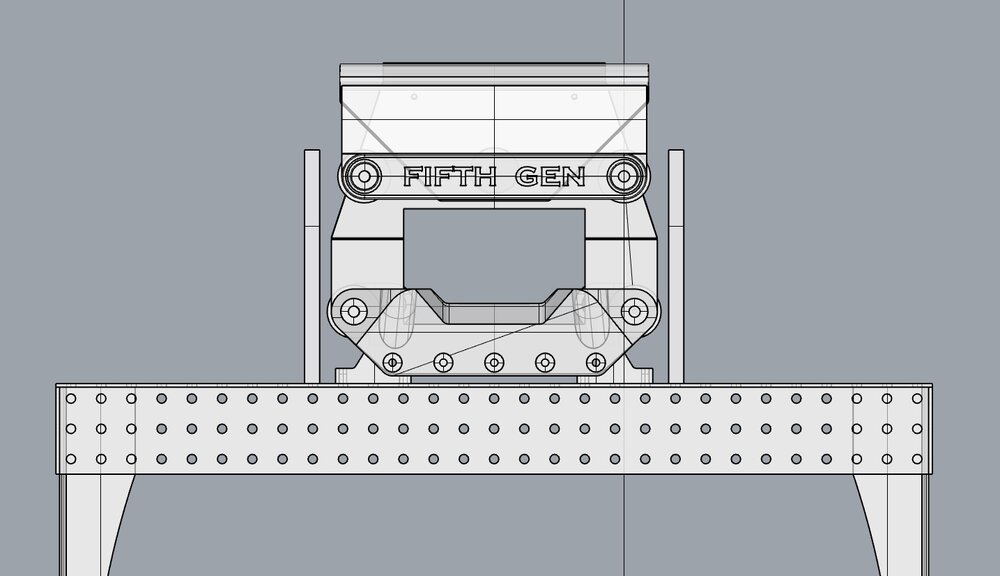

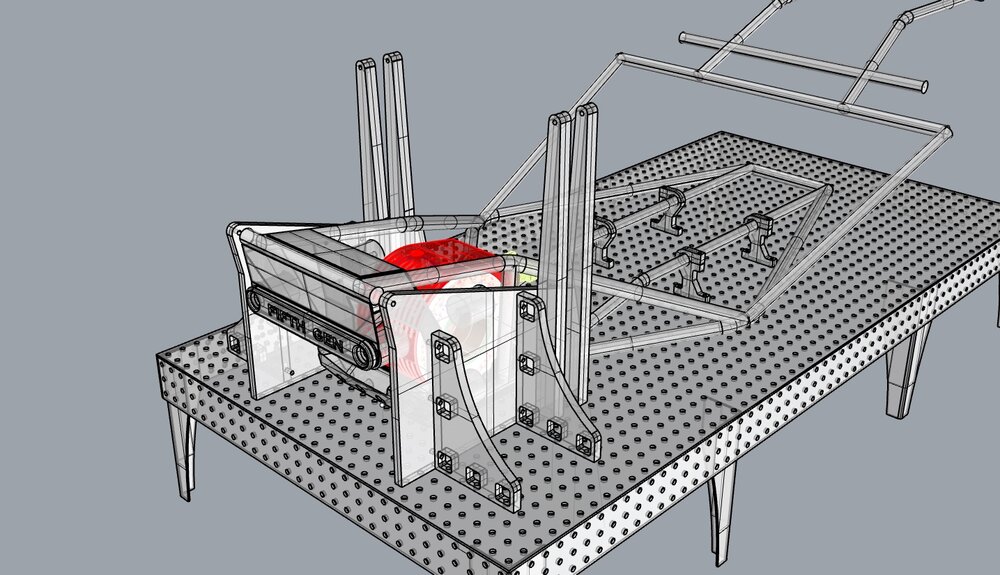

Digging into the bulkhead fixture. I'll end up making everything interlock & bolt together symmetrically so nothing's mirrored. So the fixture pieces can do the same job on either side, and cuts the cost to machine.

Last edited:

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

Looking at it now, I may try to incorporate mounting that sway bar tube.

Last edited:

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

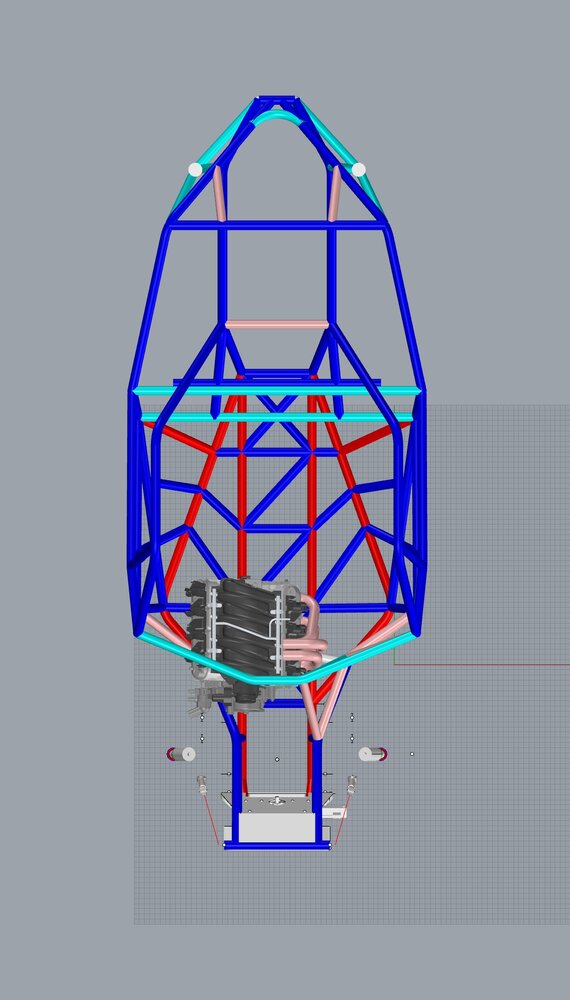

Walked right into a way to find my shocks. Wonder what other things I could bolt to these bulkhead plates.

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

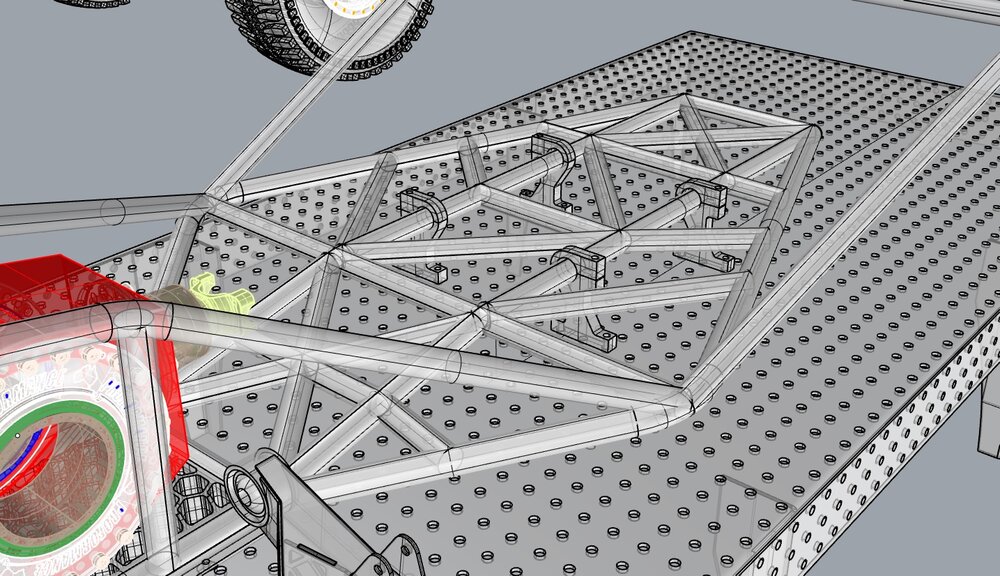

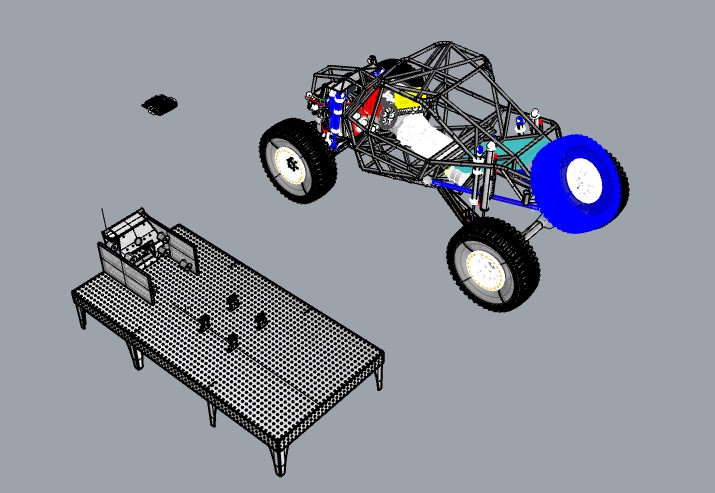

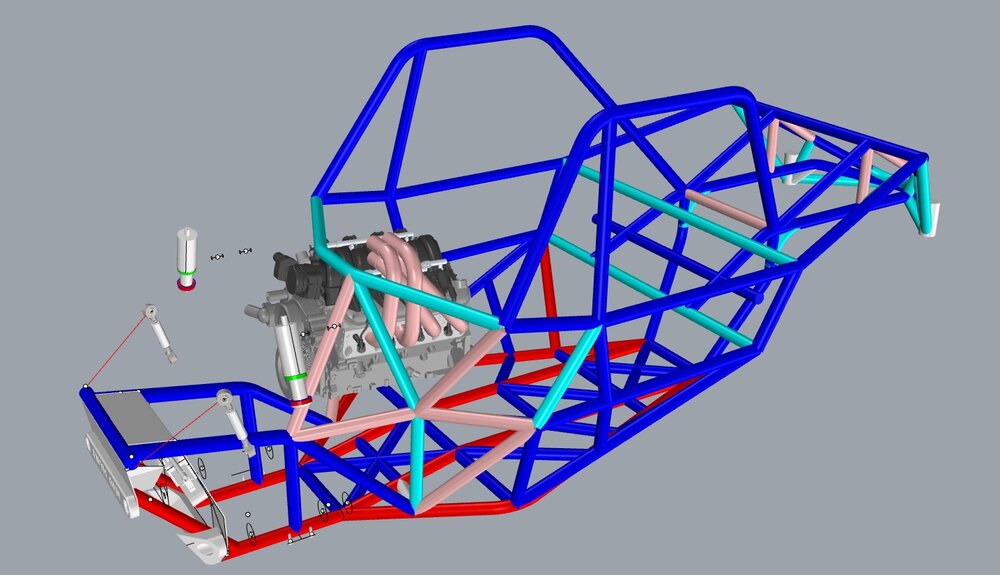

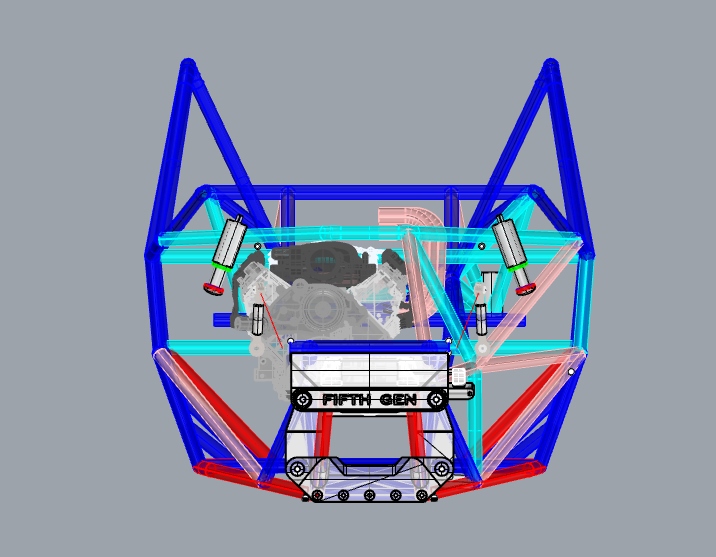

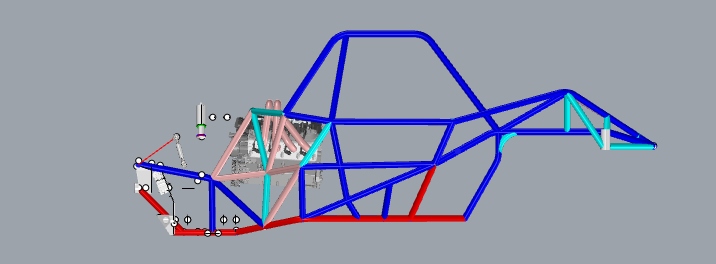

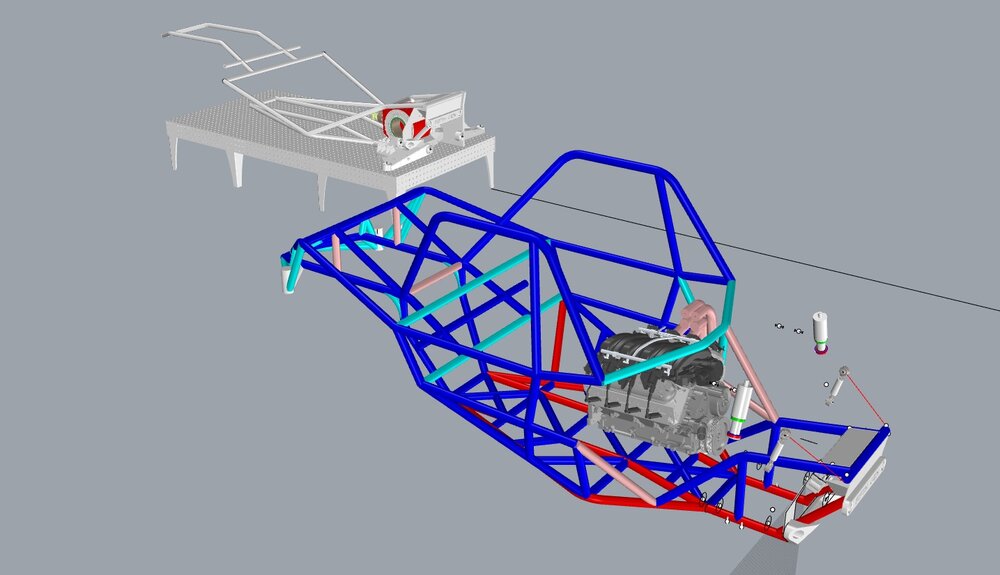

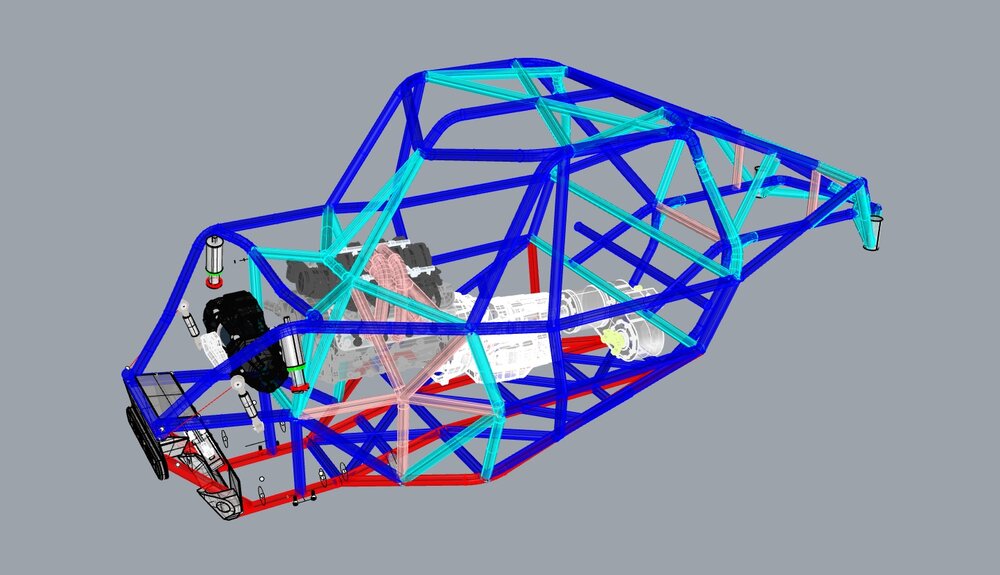

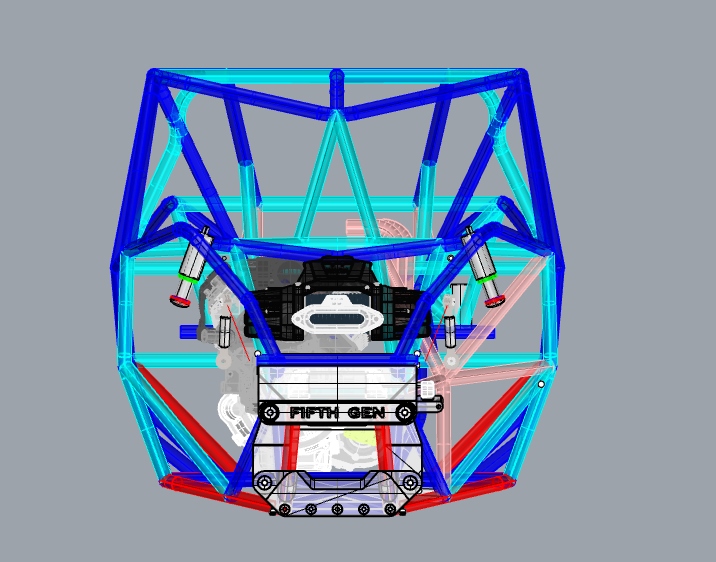

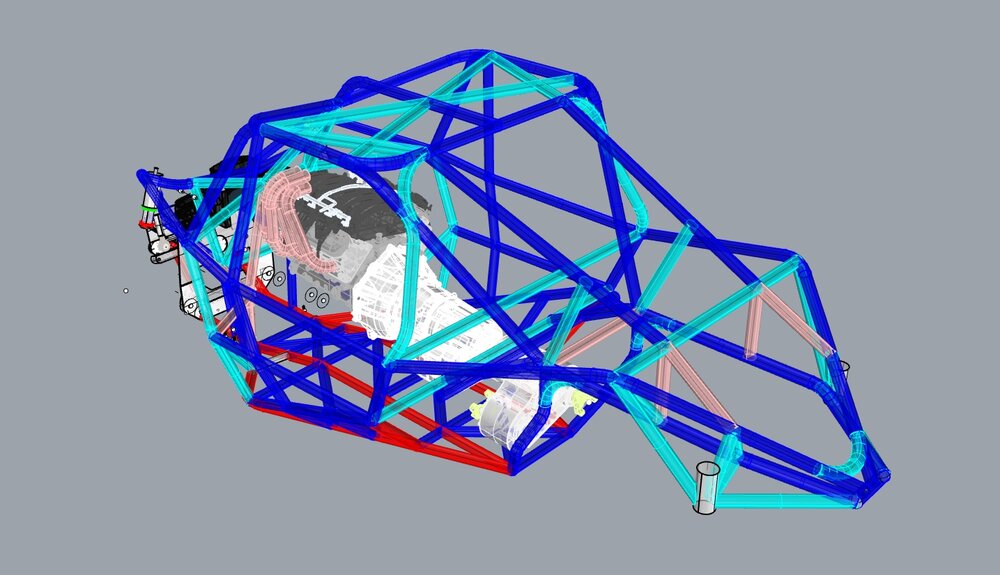

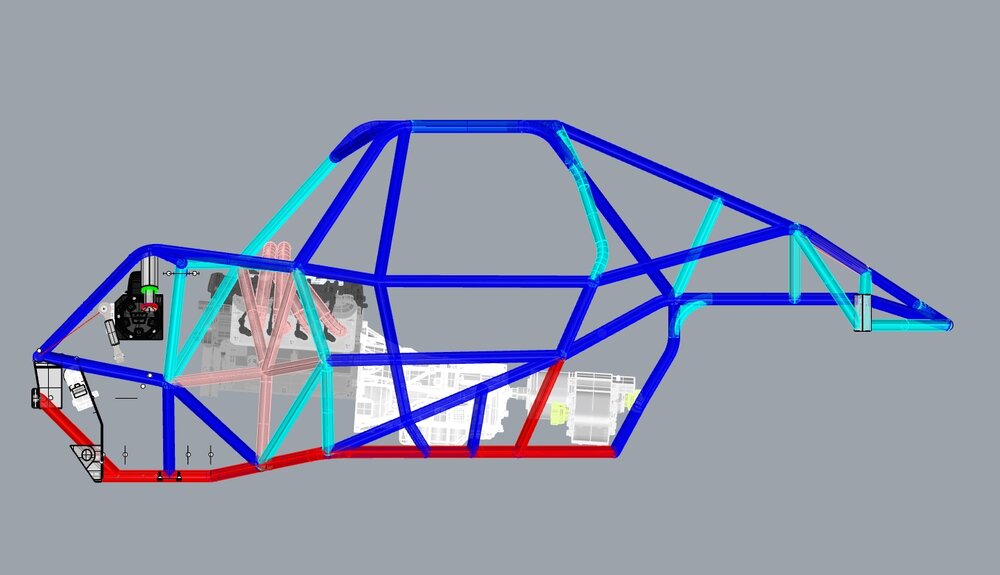

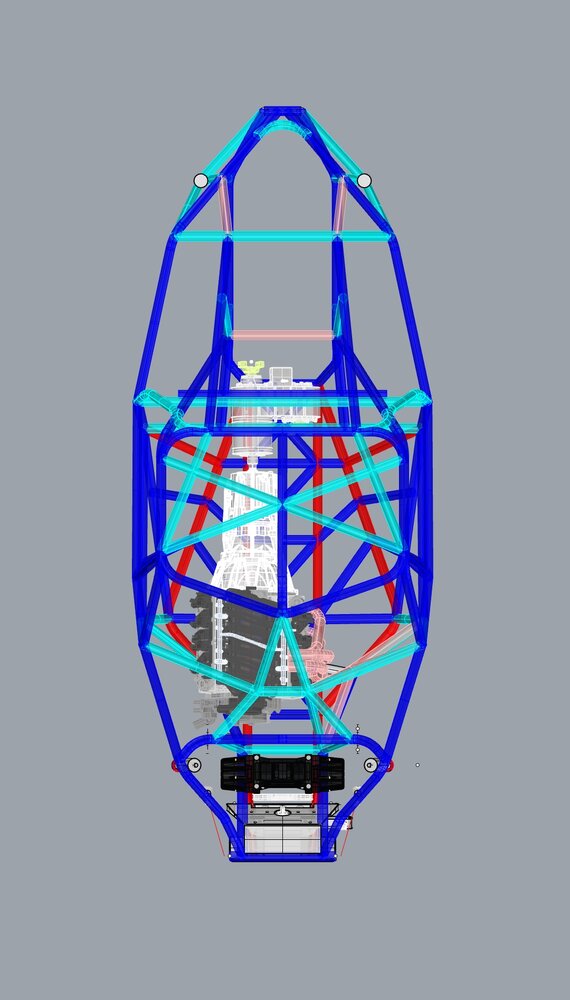

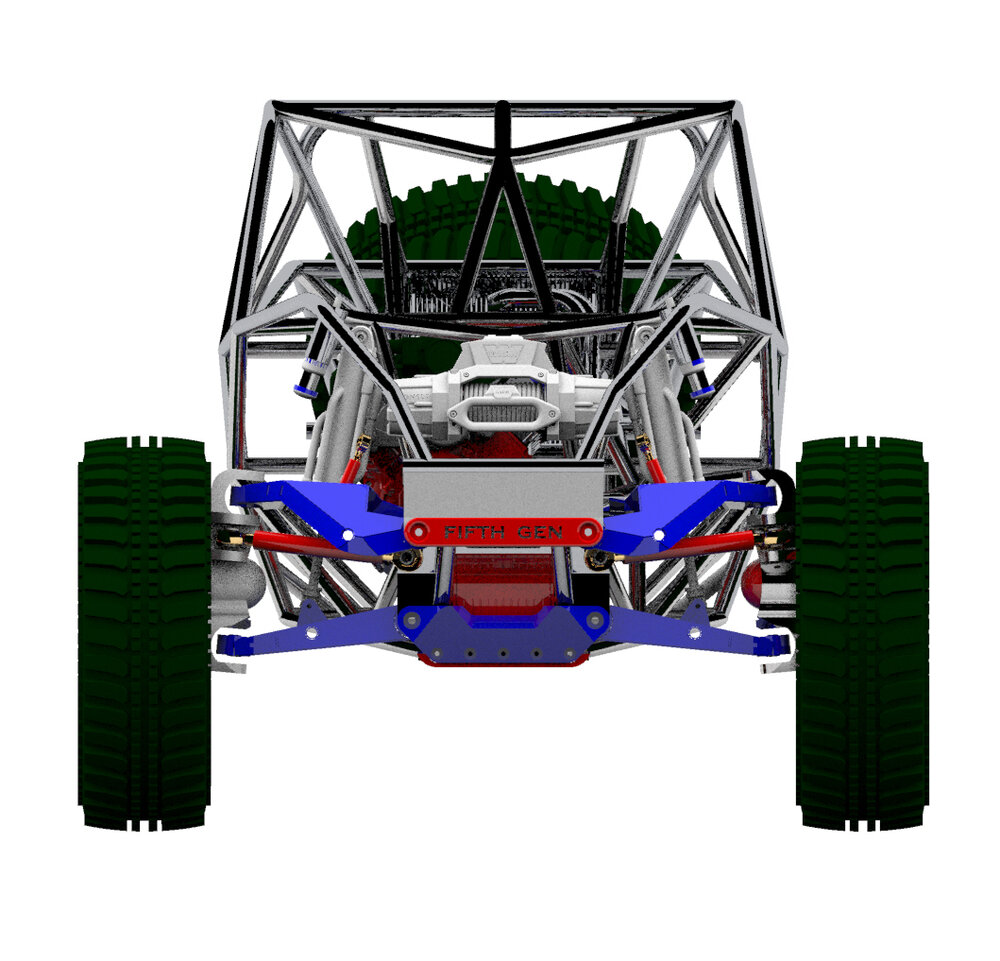

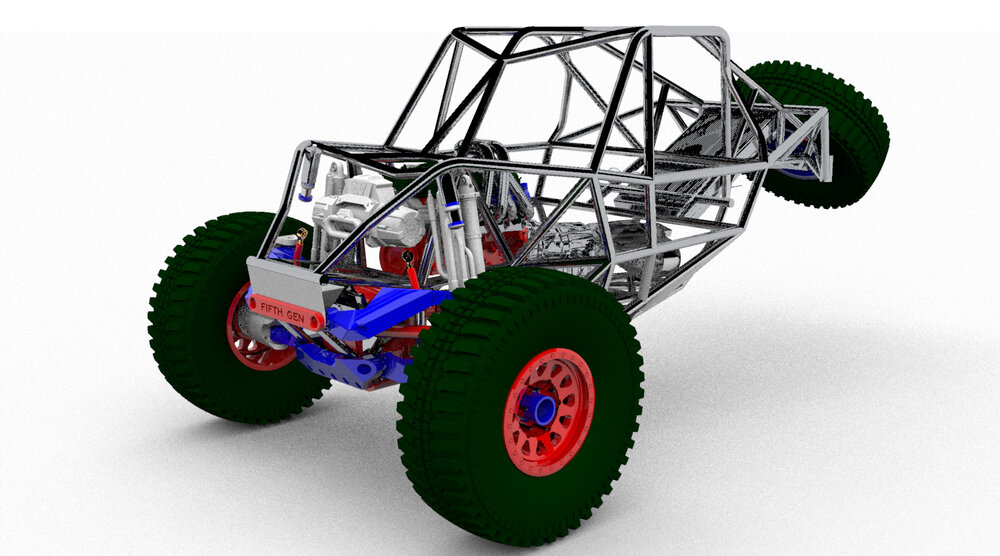

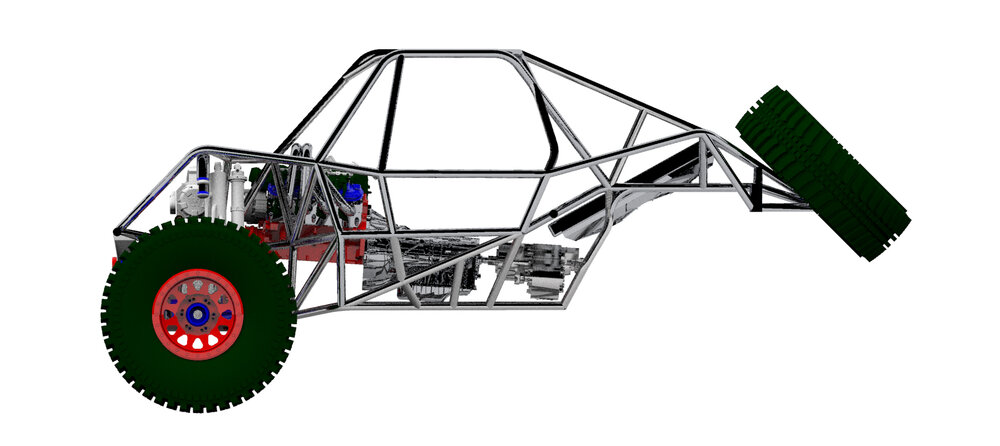

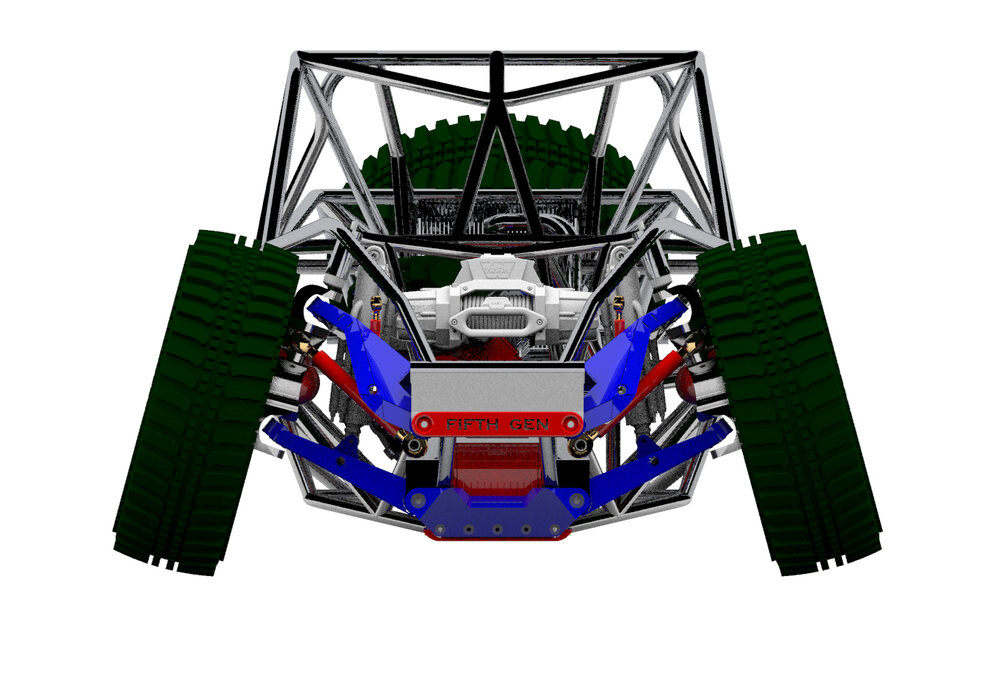

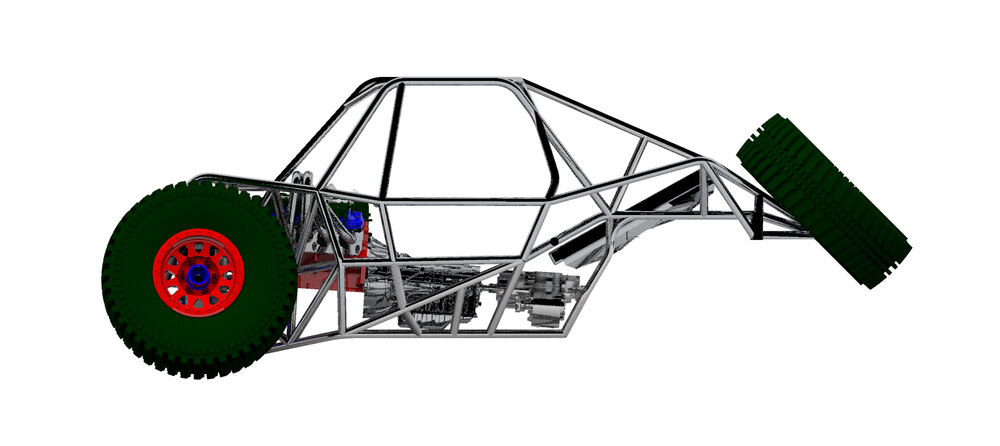

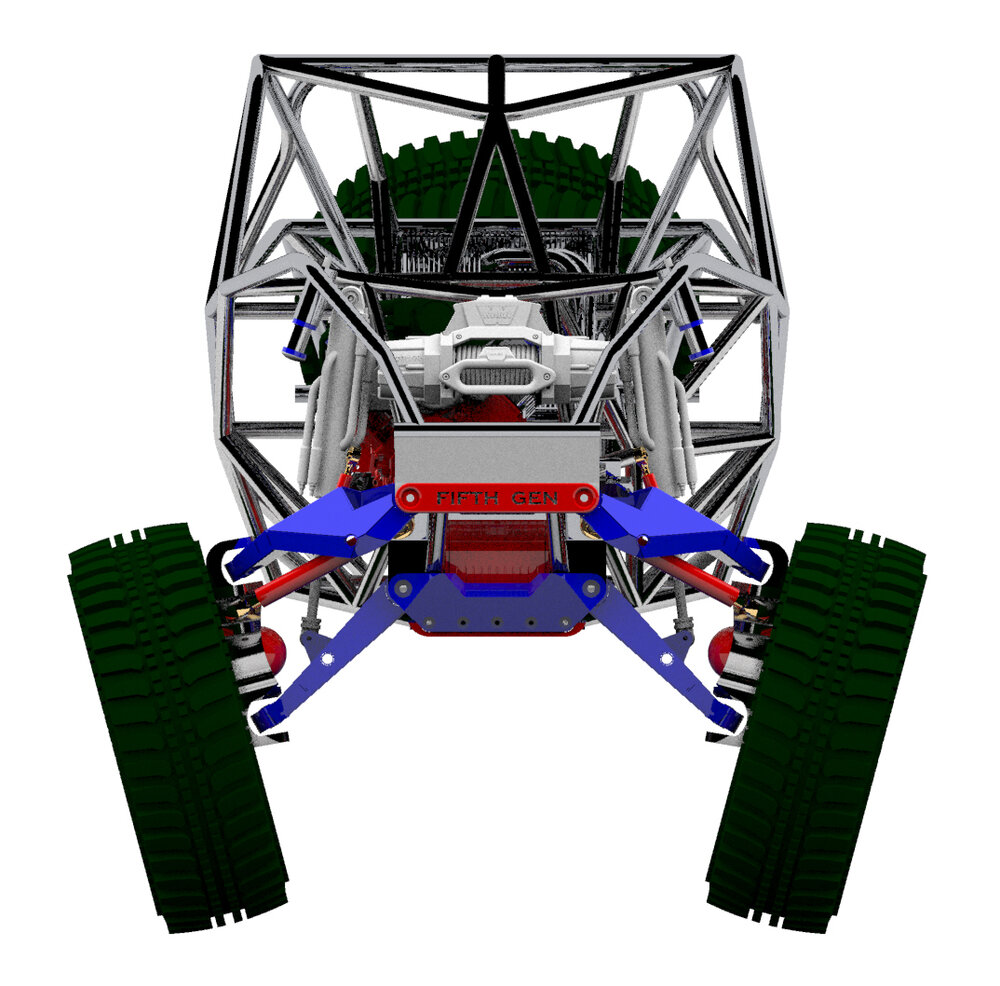

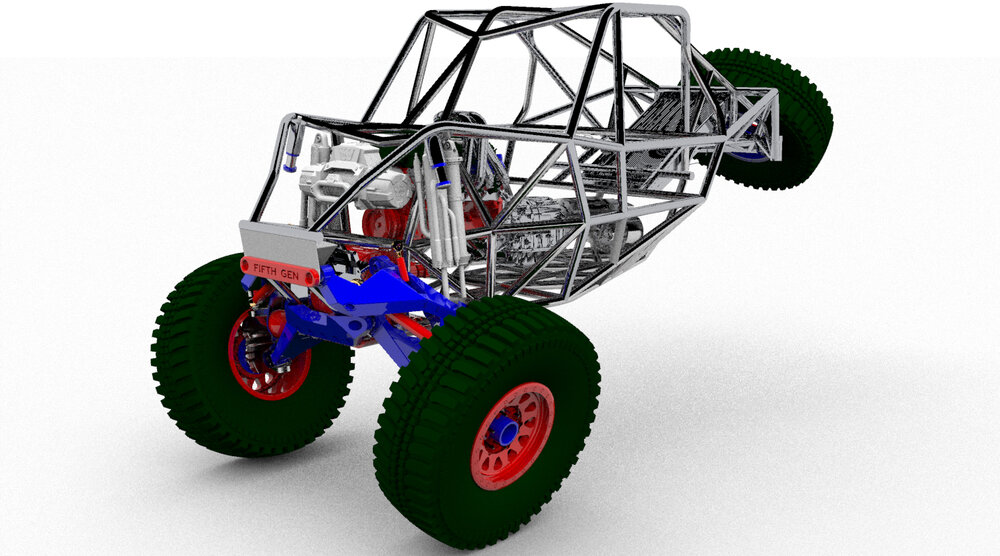

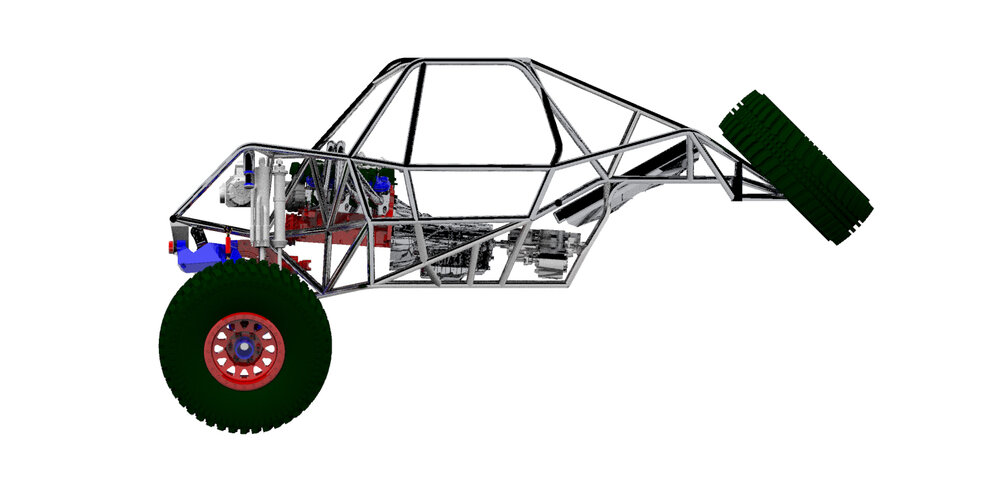

Further with the chassis.

Inch & three quarter chromoly tubing.

Legend:

Red = .188 wall

Blue = .120 wall

Cyan = .090 wall

Pink = .063 wall

The lacing around the engine won't be symmetrical with the lacing on the driver side. I've mapped the driver side though. l may end up having to stuff the tire at lock, and lace around the engine hands on. You can see a major tubing change between the colored pictures, and that one picture on the jig.

Inch & three quarter chromoly tubing.

Legend:

Red = .188 wall

Blue = .120 wall

Cyan = .090 wall

Pink = .063 wall

The lacing around the engine won't be symmetrical with the lacing on the driver side. I've mapped the driver side though. l may end up having to stuff the tire at lock, and lace around the engine hands on. You can see a major tubing change between the colored pictures, and that one picture on the jig.

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

I know how to mount the front shocks now.

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

ok now lets see one built

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

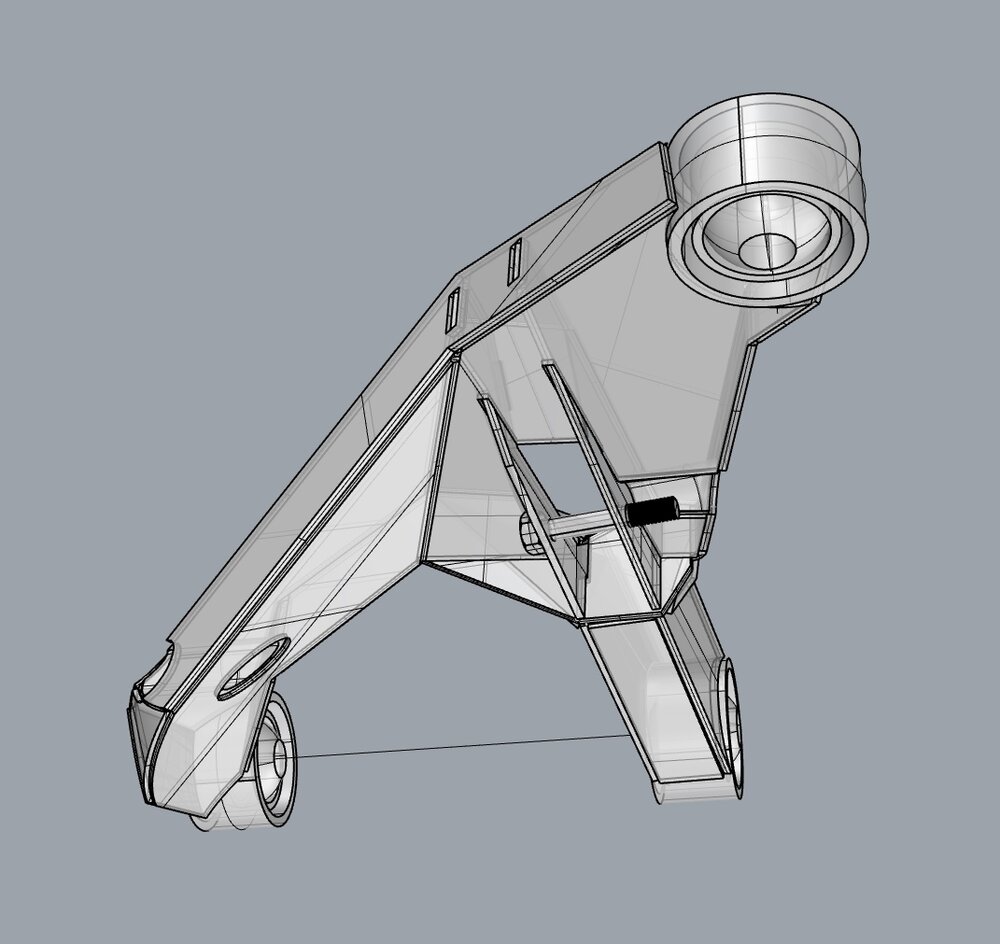

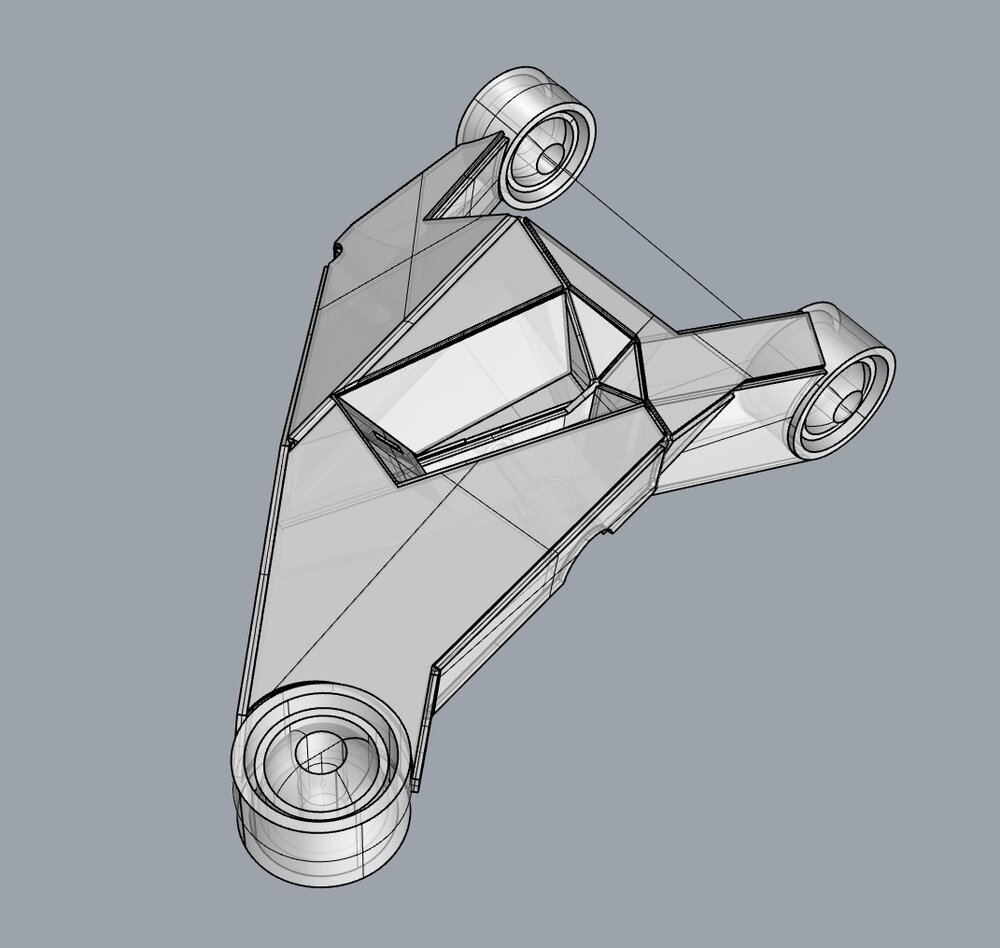

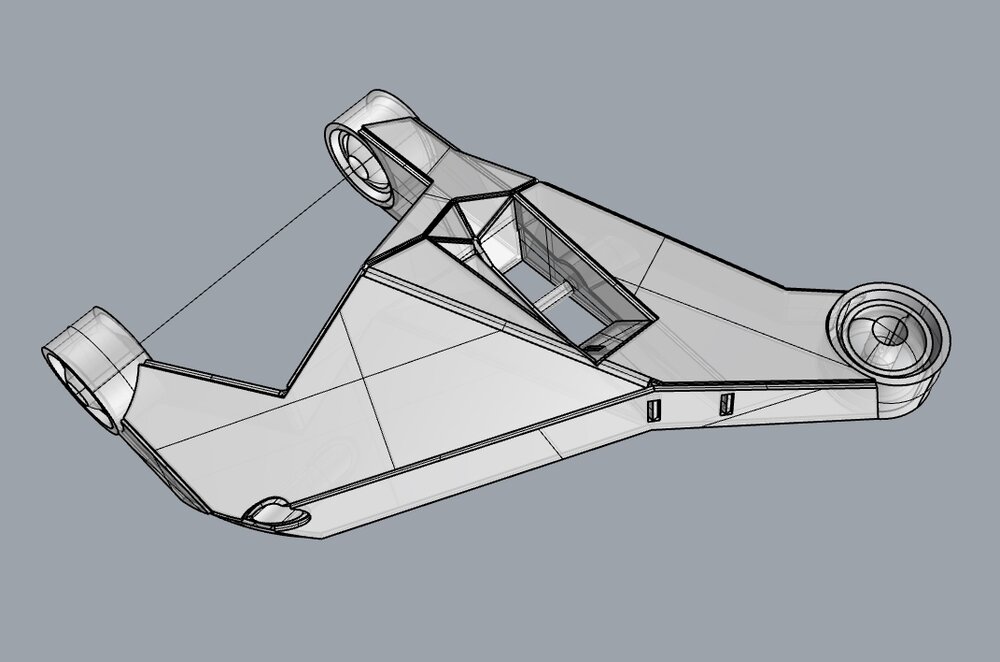

Absolutely insane amount of work into this upper control arm, but I think it's done. I would never be able to create something like this by hand. Motobilt technology opening up doors for some speed. The hard work is done. Unbelievable.

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

What's going on here:Absolutely insane amount of work into this upper control arm, but I think it's done. I would never be able to create something like this by hand. Motobilt technology opening up doors for some speed. The hard work is done. Unbelievable.

View attachment 356794

View attachment 356795

View attachment 356796

View attachment 356797

View attachment 356798

View attachment 356799

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

What's going on here:

View attachment 356808

That particular runner snakes its way through the whole unit. The triangle piece simulates a tube structure around the sway bar hole.

MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

Frigin sick

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

That rear tire recombobulation mode is sweet!

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

Now that you have you design complete... and posted... I hope there's no intention of parent protection.