So I am learning the hard way to build a trailer. The equalizer is rated for 7000 lbs. So I need to look for other options. Any ideas? I also see that I overlooked the shackle angle as well. I am guessing that I will have to move my front and rear spring hangers.

Here is my shackle angle. Where can I get the right equalizer setup?

Thats what I was talking about.

Just want to help, I'm not trying to put you or your trailer down, Thats why I ask stuff like " Why did you do it this way"

I could learn from you or maybe help you on what I have done.

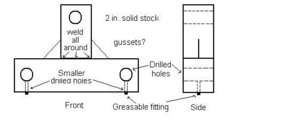

As for this problem you can find them at any trailer builder like hudson or kraftsman or maybe make you own its not hard.

If you go the way of getting one like the ones most use it will make you change you springs and all mounts because they use a slipper spring like this - front is eye mount then slipper to Eq then rear spring is eye mount to EQ and slipper to the rear.

check out some of the big trailers out there and you will see.

Also what rockcity was talking about it is better to have the tongue mount to the outside of the trailer for less flex go look at some of the small trailers with the tongue like yours and walk on them to see the flex you get. Think of how that is driving down the road when you hit a bump.

I looked at two different trailers some time back and one with the tongue outside one like yours, the one outside had about 1" or less with me jumping up and down but the other had 3-4" of movement both were 10 k trailers.

If you put braces in it will trailer a lot better. Also front and rear of the trailer should have 6" C to tie each side of the 6" c rails, to stop the twist in the frame.

Jon